TUMAKER MINI PRO

Tumaker Mini Pro

Pellet printing opens up new possibilities in additive manufacturing, and the Tumaker Mini Pro is designed to take full advantage of them. This system allows the direct feeding of polymers in pellet form, eliminating the need to process them as filament, reducing costs and maintaining the original material properties.

In addition, the ability to work with recycled polymers and other advanced materials improves sustainability and broadens applications in sectors such as research, design and industrial production.

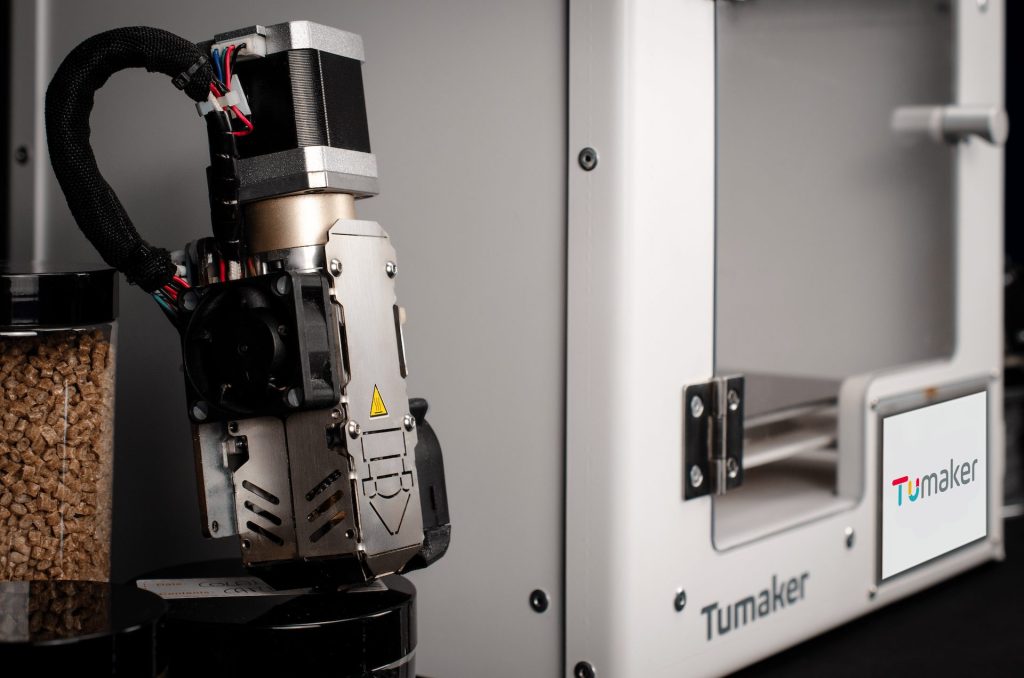

Pellet Extruder: Advanced and cost-effective 3D printing

Pellet printing opens up new possibilities in additive manufacturing, and the Tumaker Mini Pro is designed to take full advantage of them. This system allows direct feeding of polymers in pellet form, eliminating the need to process them as filament, reducing costs and maintaining the original material properties.

In addition, the ability to work with recycled polymers and other advanced materials improves sustainability and broadens applications in sectors such as research, design and industrial production.

Key features of the pellet head:

- Compatible with the Pellet Feeder

- Pellet size recommended: 3 to 5 mm diameter

- Maximum die temperature:300 ºC

- Adjustable nozzles: 0,4 mm | 0,6 mm | 0,8 mm (included) | 2,0 mm | 4,0 mm | 5,0 mm

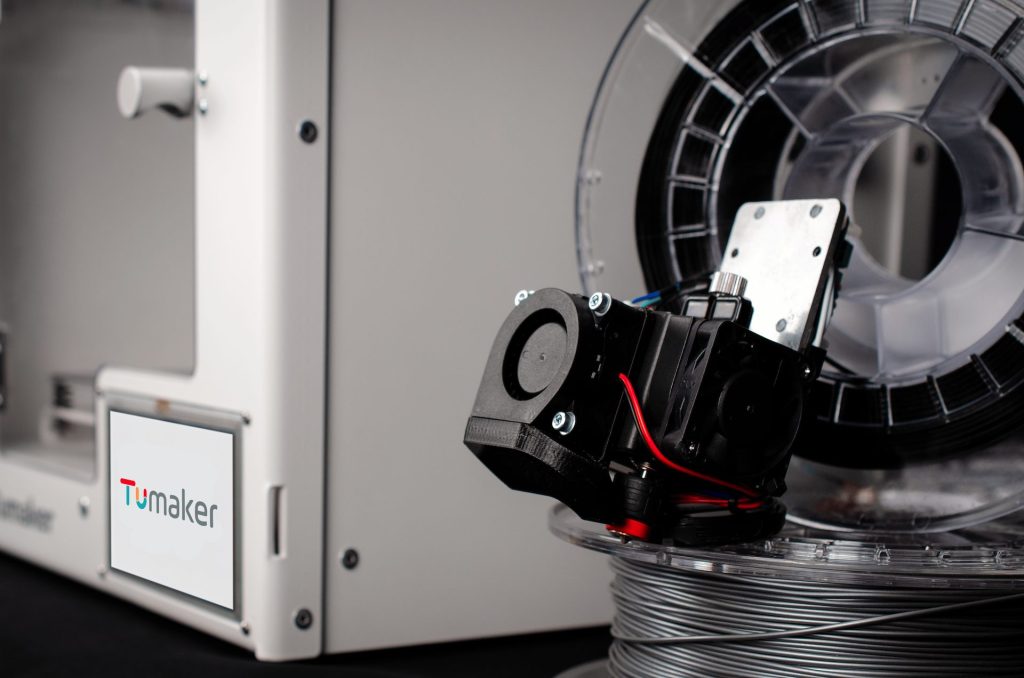

Filament Extruder: Precision in a Compact Format

For those looking for precision and ease of use, the Tumaker Mini Pro 3D printer’s Direct Drive HR filament extruder is a versatile tool that allows you to work with a wide variety of materials. From standard plastics such as PLA and ABS to advanced polymers such as TPU, this head ensures consistent results even in complex projects.

Roll handling and the ability to adapt to different needs make it a flexible solution for creative, educational and industrial applications.

Filament head features:

- Compatible with spools up to 1 kg

- Maximum head temperature: 300 ºC.

- Interchangeable nozzles: 0.15 mm | 0.25 mm | 0.4 mm (included) | 0.6 mm | 0.8 mm.

- Optimized materials: PLA, ABS, ASA, PET-G, NYLON, TPU, among others.

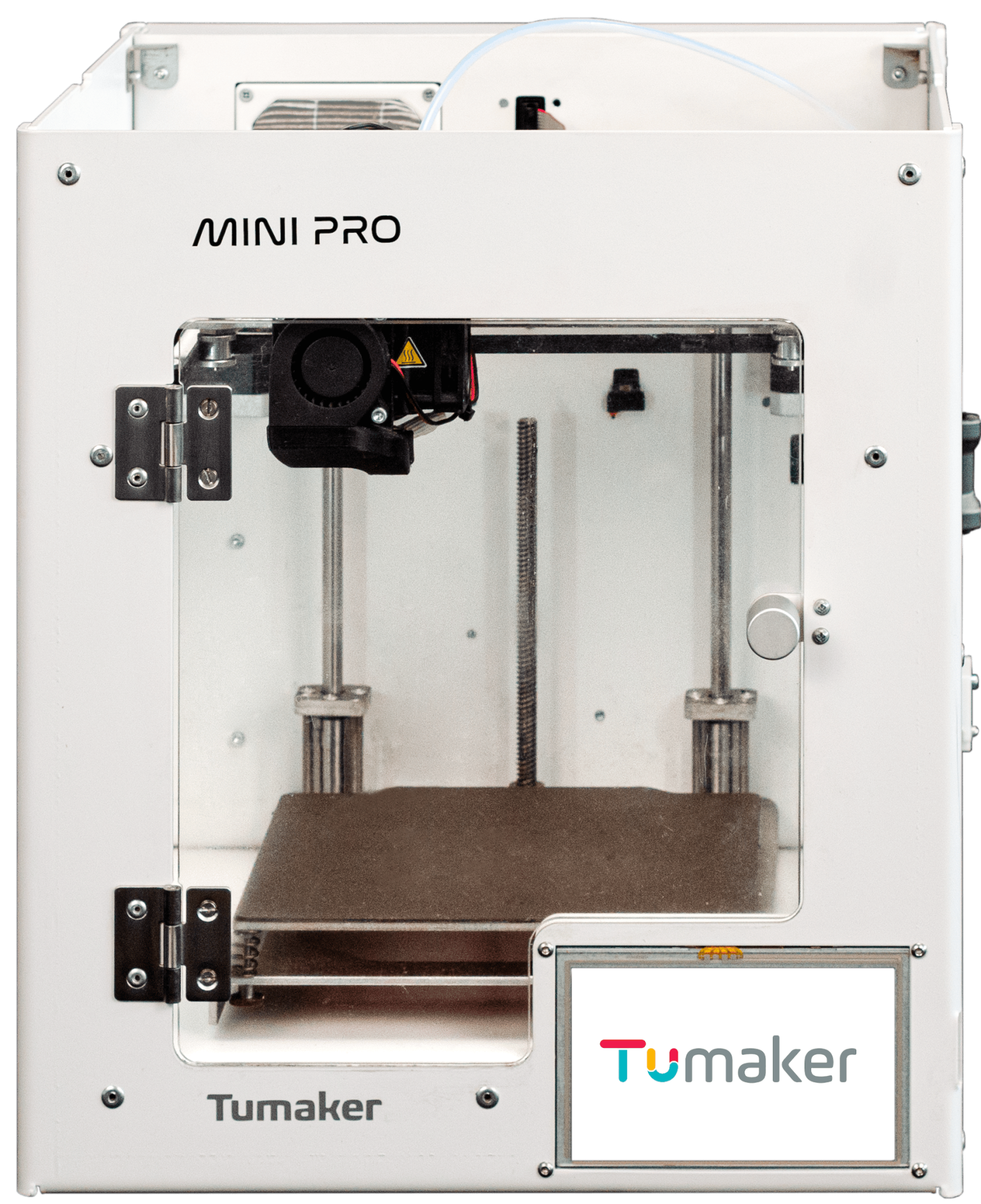

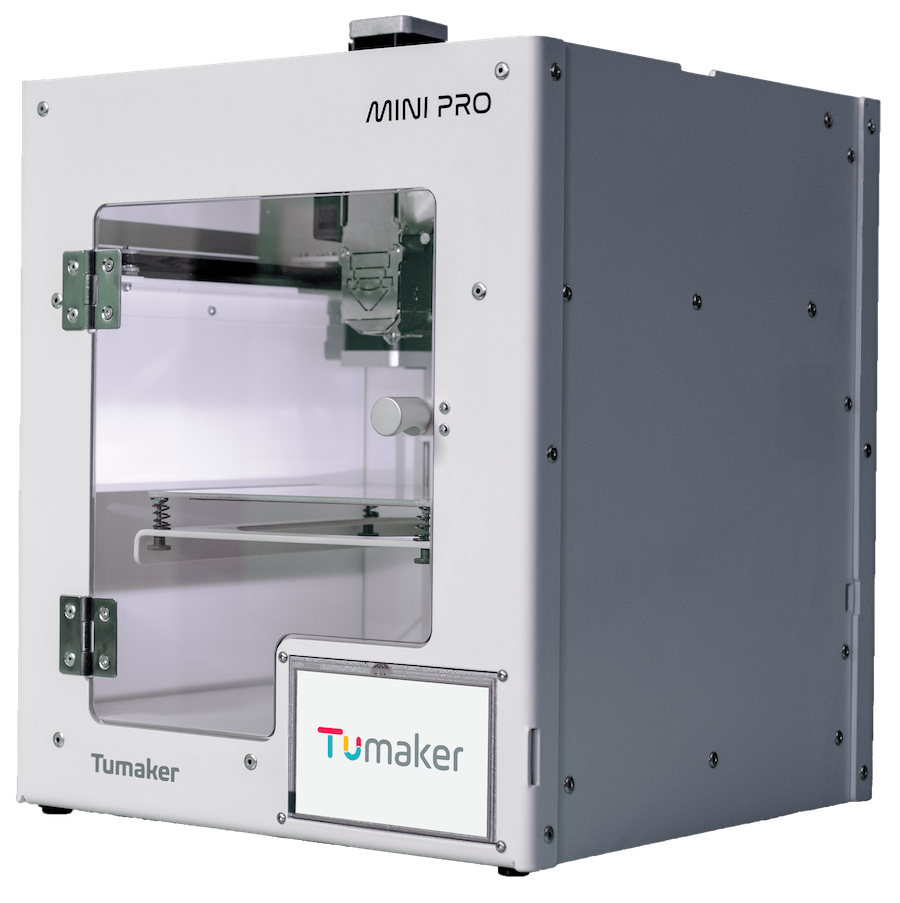

Small in Size, Big in Performance

The Tumaker Mini Pro combines its compact design with a work area ideal for small to medium-sized projects, while maintaining the precision and reliability for which Tumaker is renowned. Its enclosed structure and filter system ensure a clean and safe working environment, while its low noise level creates a comfortable and professional experience.

Key specifications:

- Work area: 200 x 200 x 200 mm.

- Automatic calibration, which simplifies the start-up process.

- Advanced connectivity: Wi-Fi, Ethernet and Micro SD.

- 5″ colour touch screen, with intuitive interface.

- Compatible with Simplify 3D, CURA and SuperSlicer, supporting formats such as STL, OBJ and Gcode.

Automatic Pellet Feeder

The perfect complement to your 3D printer with Pelletserfecto de tu impresora 3D con Pellets

The Automatic Pellet Feeder independently and directly feeds the head hopper. This mechanism frees the user and allows him to ignore the routine of manually feeding the extruder.

Unifying in the same 3D printer the advantages of additive manufacturing with Pellets and the automation made possible by the Automatic Feeder, forms a unique machine in the sector.

The feeder has an initial tank 40 cm high to hold 7.06 dm³ of pellets. In addition, it incorporates a material end sensor at the tip to manage the automatic supply of pellets. At the base of the feeder, a temperature and humidity sensor manages this data to keep it in optimal conditions.

Characteristics

| Specification | Mini Pro (Pellets) | Mini Pro (Direct Drive HR) |

|---|---|---|

| Extruder | Pellets | Direct Drive HR |

| Compatible Nozzles | 0.4 mm, 0.6 mm, 0.8 mm, 2.0 mm, 4.0 mm, 5.0 mm | 0.15 mm, 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Included Nozzle | 0.8 mm | 0.6 mm |

| Materials | Recommended pellet size: Circular 3 – 5 mm | ABS, ASA, NYLON, PET-G, PLA, PP, TPU Hardness, TPU… |

| Print Volume | 145 x 115 x 150 mm | |

| Printer Weight | 10 kg | |

| Printer Dimensions | 350 x 350 x 380 mm | |

| Package Weight | 12 kg | |

| Heated Bed Temperature | Up to 100 ºC | |

| No. of heads | 1 | |

| Head Temperature | Up to 300 ºC | |

| Calibration | Automatic | |

| Structure | Closed with filters | |

| Connectivity | Wi-Fi, Ethernet, Micro SD | |

| Noise Emission | 44 dB (40 dB with door closed) | |

| Display | 5” colour touch screen | |

| Compatible Software | MacOS, Windows, Linux | |

| Power | 120W, 500W, 950W | |

| Compatible Slicing Software | Simplify 3D, CURA, SuperSlicer | |

| File Format | STL, OBJ, Gcode | |

| Warranty | 1 year | |